Disposable caging improves the ability to maintain a high level of biosecurity and allows you to manage a secure process, regardless of size and scope of the facility.

Secure Process

Simpler Process and Protocols

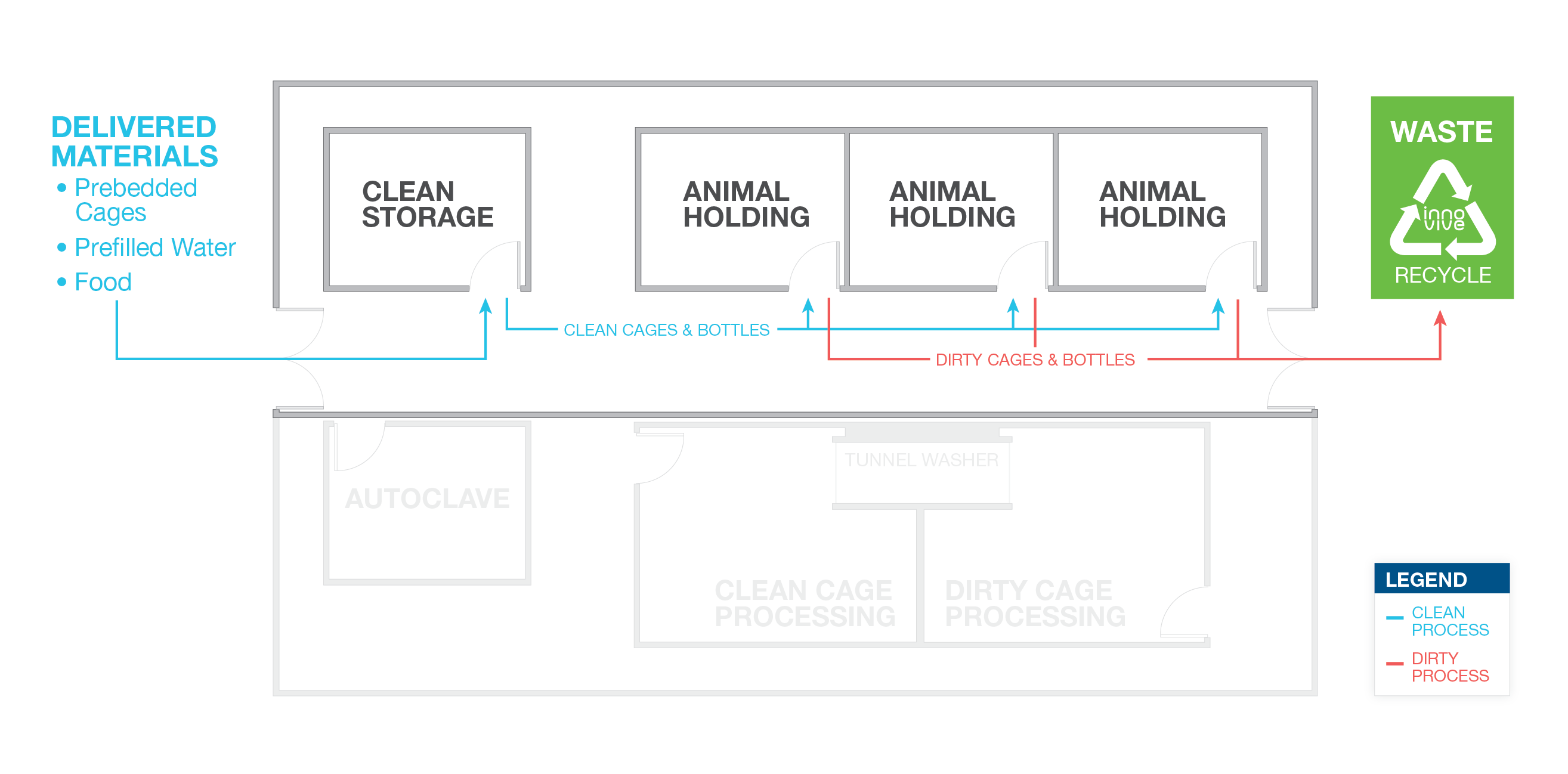

Disposable Research-Ready™ caging components follow a one-way process flow through the facility and are received directly into clean cage storage¹. The cages arrive sealed in two layers of bagging to ensure biosecurity, and the outer bag can be delayered at any stage based on your facility's flow of operation. When they are ready for use, the inner bag is typically unsealed under a laminar flow hood where cage changes are performed. Standard cage change processes are followed and animals are returned to their ventilated racks (Innorack®). Each cage has the added benefit of never having previously housed another animal.

With the Innovive Closed-Loop Recycling Service, used disposable cages can be restacked with soiled bedding and sealed back in their original bags. Afterwards, it can be taken straight to the recycling dock of the facility. The Innovive Recycling Service Team then picks up the bags of soiled cages so they can be further processed for recycling and composting.

¹ In barrier facilities, this can be done effectively by wiping down the double-bagged configuration or stripping off the outer bag as you enter the facility or using a misting tunnel as the point of entry. There is a high degree of flexibility in how direct-to-clean storage is implemented at any facility.

Disposable vs. Traditional Caging

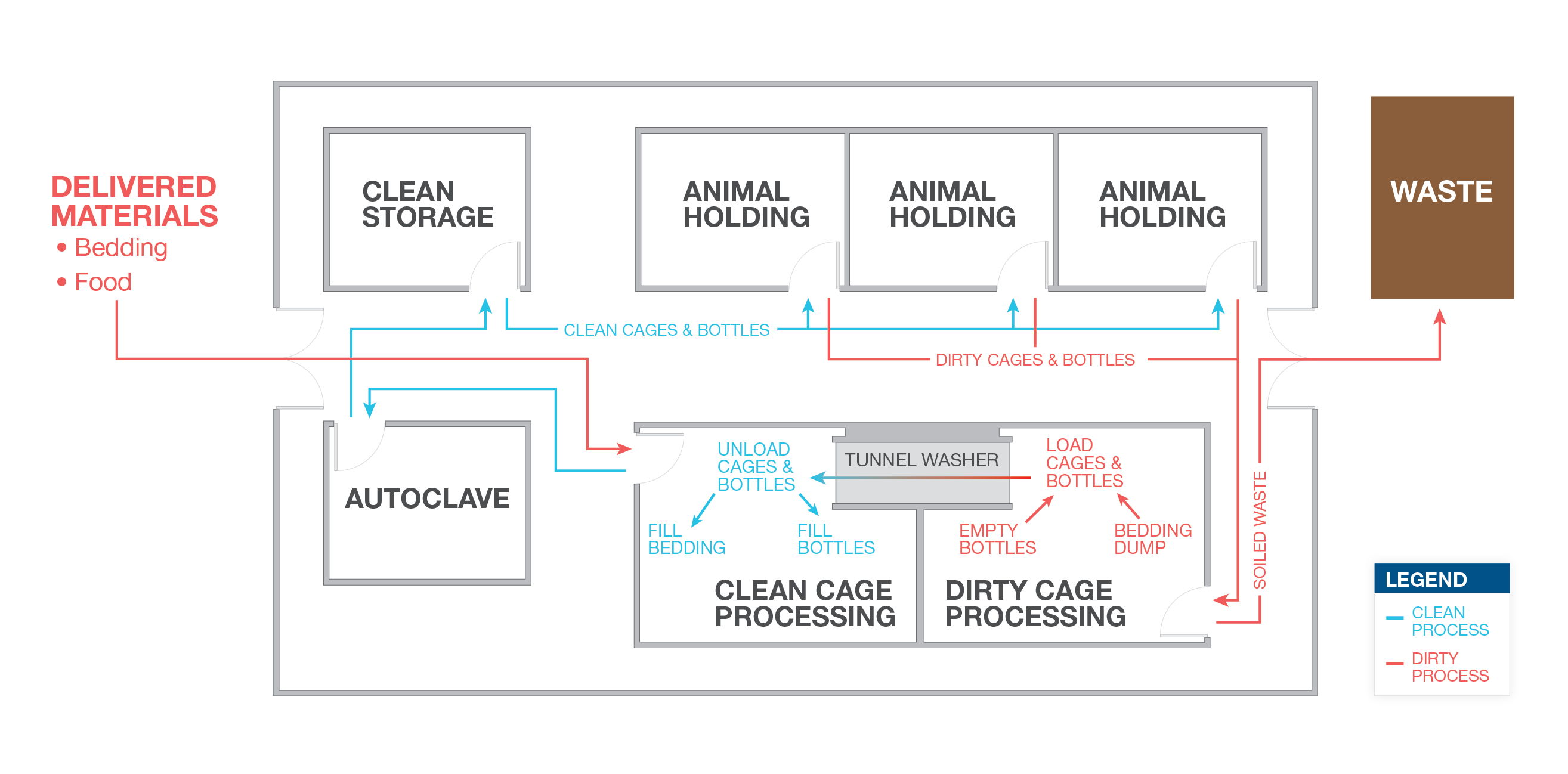

The diagrams below provides a comparison between a traditional and disposable caging facility. It illustrates the simplified process and material flow that occurs in a disposable caging facility.

By comparison, caging in a traditional facility follows a return loop to the dirty cage wash area. There, the bedding is dumped and used cages and bottles need to be thoroughly washed. Fresh bedding and water are added to cages before everything is sterilized and delivered back into clean storage. This entire process requires strict adherence to SOP protocols to maintain separation of the dirty and clean areas of the facility, such as dirty hallway traffic control.

The Innovive system offers a simpler workflow at your facility, and allows you to control a secure process. As a result, the Innovive system will improve your biosecurity profile.

Discover more about the biosecurity of Innovive products by viewing our "How Clean is Your Cage?" webinar.

Previous: Disposable Cages 101

Previous: Disposable Cages 101